Existing Production Line Upgrading / Improvement / Refurbished / Modify

We offer comprehensive services to upgrade, improve, refurbish, and modify existing production lines. Our goal is to enhance the productivity, safety, and longevity of your equipment, ensuring that your operations run smoothly and efficiently.

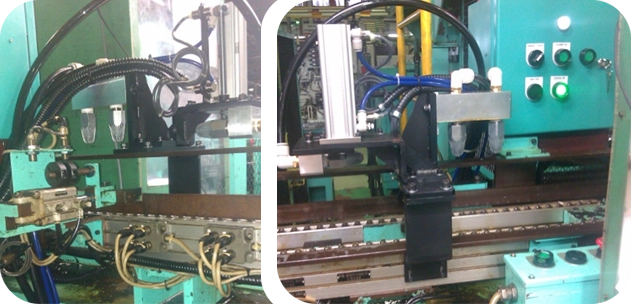

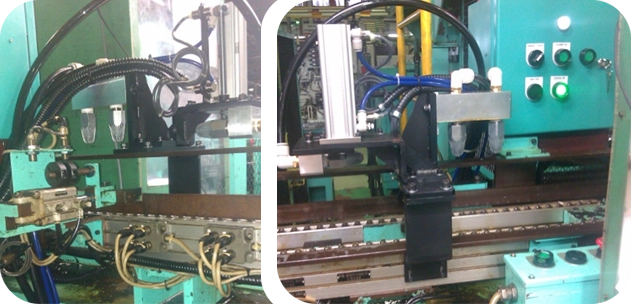

Refurbish Machine

- Modify Jig & Fixture of Machine

- Replace all damage and broken parts for mechanical and electrical

- Service all pneumatic valve and actuator

- Service pump and filter

- Rearrange all messy wiring and tubing

- Repainting Machine

- Test and Commissioning

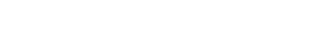

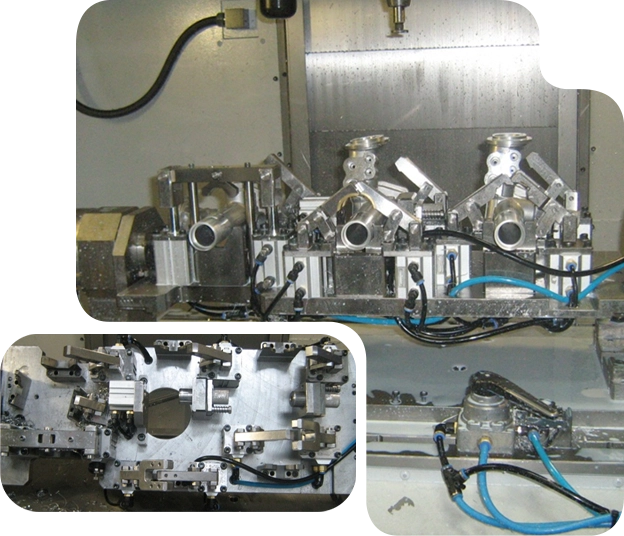

Jig & Fixture

- Turn Table, Jig & Fixture Design for 5-axis CNC Machine

- High Accuracy Up to ±0.025 mm

- 3 Station of Operation Process

- ±90° Jig Table Turntable

- Mechanical Valve Clamping Control System

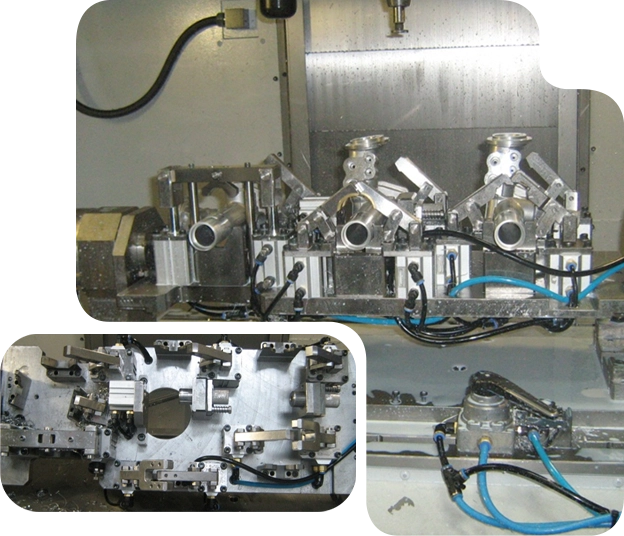

CYL Head Marking Machine

- Additional Marking Process into existing conveyor line

- Marking for Engine Model No.

- RFID Reader is used to read data from pallet

- Micro-percussion indent marking units

- Built with PLC control and Electrical Operation Panel

CYL Head Air Blower Machine

- Additional Air Blower process in the existing conveyor line

- Remove Coolant from Valve Holes before Sealing

- Built with PLC control and Electrical Operation Panel

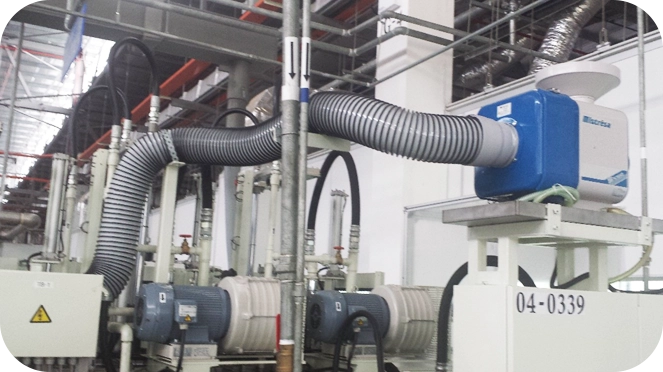

Mist Collector Installation For Washing Machine

- Additional Mist collector for existing washing machine

- Existing PLC program and wiring modify

- Mist collector structute and hose ducting installation